Background

Like any good project, we started at the beginning. And the beginning of any good weatherization project starts with an energy audit. Originally built in 1980, our house is structurally sound. However its vintage, along with a series of additions over time, left me curious about its energy performance. Thanks to VEIC’s Sustainability Benefit, our cash outlay for this initial investigative step was paid for.

We moved in during the spring of 2018. Amidst the multitude of resulting house projects, I translating the original audit findings into a visual scope of work and solicited contractors for competitive pricing to address (3) major projects: 1) spray foam insulation in band sills and within crawl spaces; 2) insulating the basement walls; and 3) adding blown cellulose to the attic.

As summer turned to autumn (and I was admittedly a bit delayed in hiring out these jobs before winter arrived), Vermont’s Button Up campaign kicked off. We volunteered our home for WCAX’s series on weatherization efforts, including the campaign kickoff, the value of an energy audit, attic air-sealing, and Efficiency Vermont’s Do-It-Yourself weatherization program. After comparing the best contractor pricing to the cost of materials and my time, I opted to see what could be tackled on my own.

Basement Walls

The energy audit called out adding spray foam or foam board insulation to the basement walls from the top of the foundation down to 4 feet below grade. Since we’re also planning to expand the finished space, I thought why not insulate the entire wall to the floor.

With an extra set of hands from my dad, we made quick work of this job. Even the kids helped out. Sometimes in unusual ways.

Adventures in Spray Foam

Although it became too cold outdoors to address spray foam needs within some of the crawl spaces, I was able to make good headway in the basement areas. The band sills only had fiberglass batts stuffed inside, which served little purpose except cozy bedding for mice.

This job was perhaps easiest of the bunch once I dialed in the consistency of the foam and gained some experience with how it spread from the various nozzles.

After realizing I had plenty of foam left after finishing the band sills, I moved on to a few more challenging areas behind the pre-finished walls (which I plan to cover with paneling as part of the new room), around plumbing, and in the electrical closet.

Attic Insulation & Hatch

Last, but surely not least, was air-sealing and adding insulation to the attic, complete with a new attic hatch for the drop-down staircase. It required some serious prep work, careful planning, and coordination with my partner (dear old Dad again).

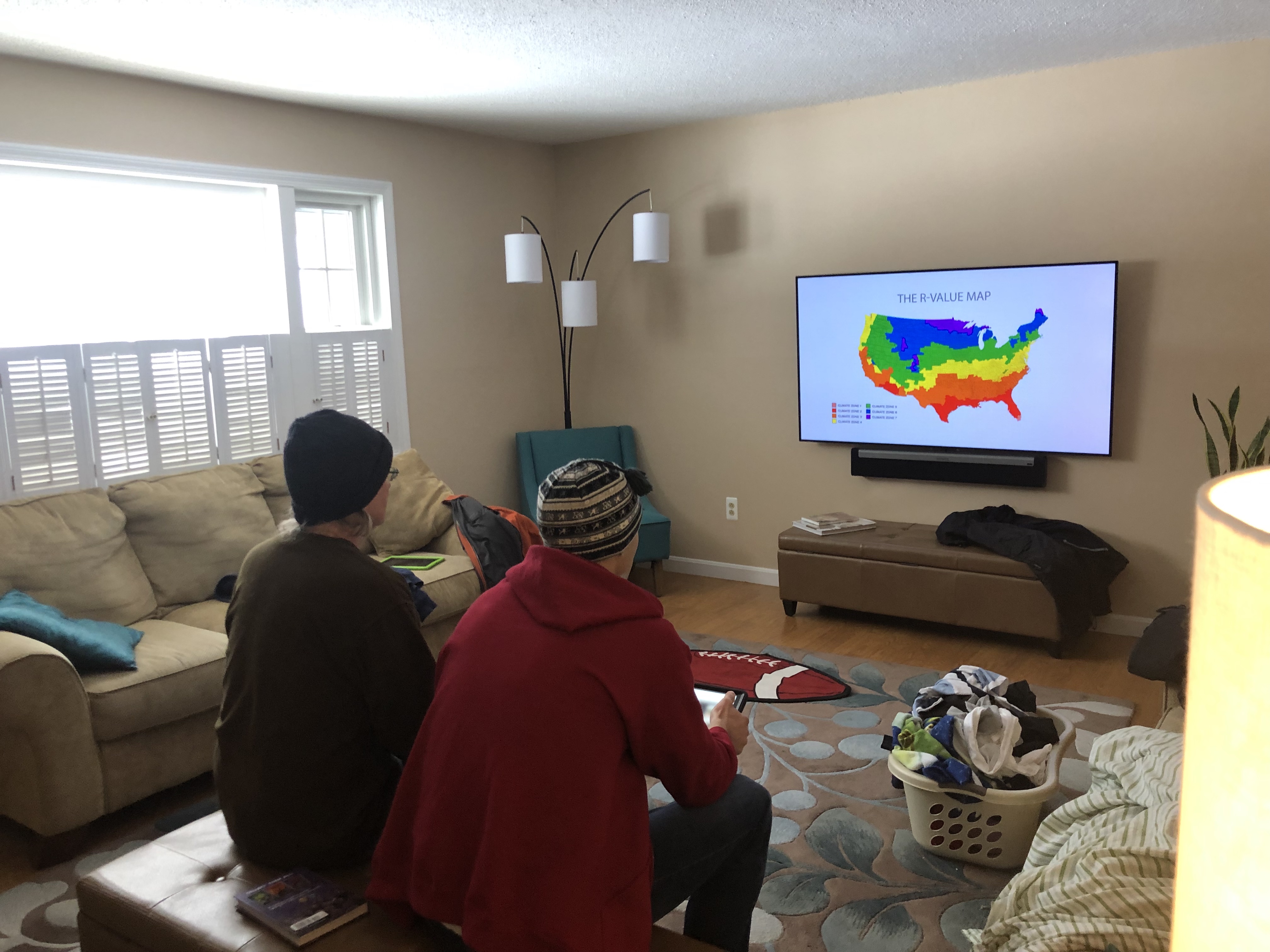

We bought a full pallet of cellulose insulation, rented the blower, and watched a few YouTube videos to determine our game plan.

And on a cold February morning, we flipped the switch and were underway. With Dad responsible for loading the hopper, I was in the attic navigating floor joists and attempting to spread cellulose as consistently as possible.

Adding 9′ of additional insulation across 1,120 square-feet (I swear it should have been 12″) took us a solid 4 hours of cellulose blowing. I wouldn’t call the job “difficult”, just maybe dirty, dusty, messy, or boring.

As the last clumps of cellulose worked their way down the hose, I reveled knowing our work was done! Before descending I put the finishing touches on the new foam cover for our attic hatch, ensuring everything was properly weatherstripped before closing the hatch for the foreseeable future.

Summary

Was it worth it? The improvements called out in the energy audit are expected to save $500 +/- in energy costs each year. For the original price estimate of ~$20K, this was admittedly a difficult pill to swallow in one gulp. We didn’t qualify for Vermont Gas’ high-use program (the previous owners were away in southern climates for most of the winter) and no amount of creative financing can turn a 40-year payback into cash-flow positive.

However, after enduring the heat last summer by having to sleep downstairs for sometimes days on end, our motivation to move forward was largely driven by comfort issues ahead of the upcoming winter. Addressing the basics — more insulation in the attic and properly air leaking in the basement — is like adding a warm hat and socks to our home. Competitively bidding the jobs dropped the price tag to more like $12K. Tackling the big jobs on our own halved the cost again.

Special thanks to my Dad for his hard labor, Erin as our TV star and videographer, Matt Sargent of Efficiency Vermont for his expertise, and the kids for their entertainment value. I’ve undoubtedly invested more than a few hours scheming and implementing our game plan. But watching our fossil fuel use drop over the coming months and the ability to sleep without a parka will surely be worth it.